Understanding Length, Width, and Height: A Clear Guide for Accurate Packaging

When ordering custom boxes or preparing products for shipping, three simple words hold significant power: length, width, height. These measurements determine how your product is packed, shipped, stored, and even displayed. Misunderstanding these dimensions can lead to poorly fitting packaging, increased shipping costs, or product damage.

This guide from Custom Packaging Pro will explain what each term means, how to measure them correctly, and why they matter — especially in the packaging world.

What Is the Standard Order of Length, Width, and Height?

You’ll often see dimensions written in this order:

Length × Width × Height (L × W × H)

Here’s what each means:

- Length: The longest side when the box is lying flat.

- Width: The shorter side of the base, next to the length.

- Height: The vertical distance from the base to the top of the box.

📦 Example: If a box measures 18" long, 12" wide, and 6" high, the dimensions are written as 18 × 12 × 6 inches.

This standard order helps avoid confusion during production, printing, or shipping.

Why These Dimensions Matter

Understanding length width height isn’t just for manufacturers. Whether you're:

- Shipping a product,

- Ordering custom printed boxes, or

- Designing retail-ready displays,

…these dimensions affect every aspect of your packaging decision.

1. Shipping Costs

Carriers use dimensional weight (DIM weight) to calculate shipping fees. It’s based on the volume your package occupies, not just its actual weight. If your box is oversized due to inaccurate dimensions, you could end up overpaying.

2. Product Fit

When packaging doesn’t match your product’s shape, it can result in movement during shipping. That leads to product damage, poor presentation, or wasted space.

3. Storage Efficiency

Knowing the correct length, width, and height helps in planning warehouse storage. Stacking, shelving, and organizing become easier with consistent sizing.

Common Confusion: When the Order Changes

While L × W × H is standard, some industries or contexts flip the order based on the orientation of the product. This can be confusing unless clarified.

Here are common alternatives:

✅ Height × Width × Length

Used when referring to upright or vertical packaging. For example, standing pouch bags or tall boxes.

✅ Length × Height × Width

Seen when depth or thickness is a key feature — for instance, book-shaped boxes.

👉 Tip from Custom Packaging Pro: Always confirm the order when providing measurements for custom packaging. Consistent communication prevents costly mistakes.

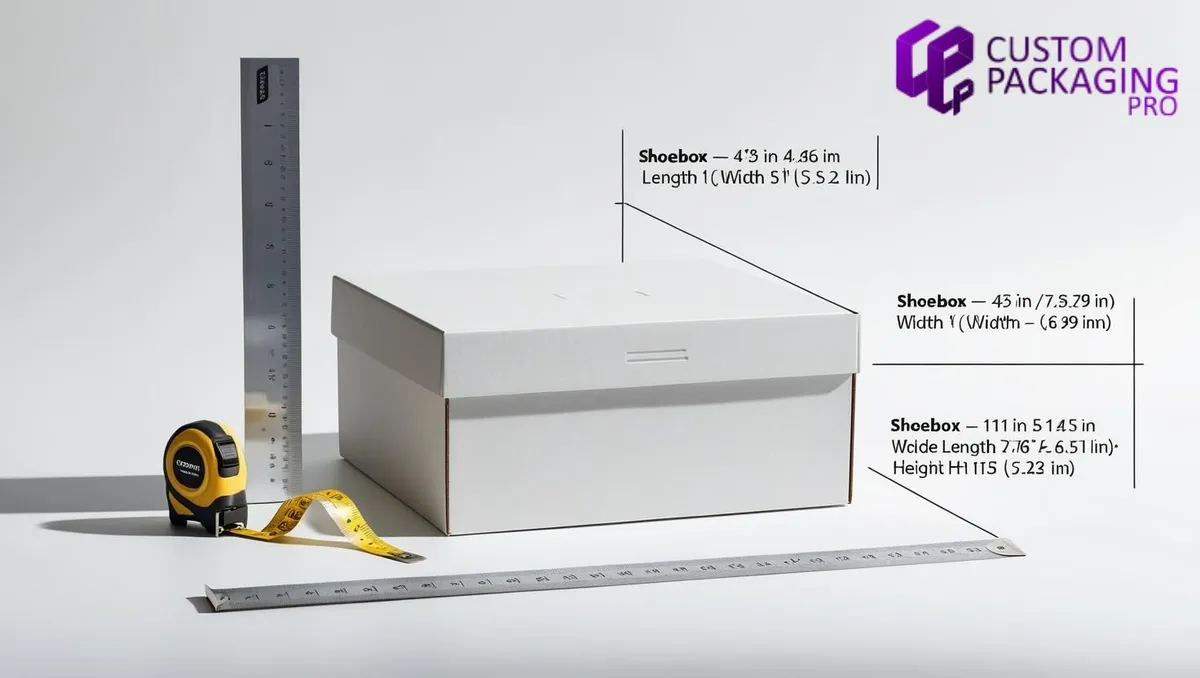

How to Accurately Measure a Box

Measuring your box properly ensures that the design, print, and product fit align perfectly. Follow this step-by-step method:

1. Place the Box on a Flat Surface

Orient the box as it will appear when opened normally.

2. Measure the Length

This is the longest side of the base. Use a tape measure and record in inches, centimeters, or millimeters as needed.

3. Measure the Width

This is the side perpendicular to the length — the shorter edge of the base.

4. Measure the Height

From the base to the top — that’s the vertical measurement.

Important: If you're measuring from the inside of the box, those are internal dimensions. If you're measuring from the outside, those are external dimensions. Clarify this when ordering custom boxes.

How to Calculate Volume Using Length, Width, and Height

The formula to calculate volume is straightforward:

Volume = Length × Width × Height

🧮 Example:

A box that is 10 inches long, 8 inches wide, and 4 inches high will have a volume of:

10 × 8 × 4 = 320 cubic inches

This is particularly useful when comparing packaging options or calculating DIM weight for shipping.

Real-World Application in Custom Packaging

At Custom Packaging Pro, clients often ask for specific packaging designs that perfectly fit their product. To deliver accurately:

- We rely on the client’s provided length width height.

- Our engineers create dielines based on those numbers.

- We optimize the space to reduce material waste and shipping weight.

Pro Tip: Always provide dimensions in the correct order and specify whether they’re internal or external.

Frequently Asked Questions (FAQs)

Q1. What does length width height mean?

A: Length, width, and height refer to the three-dimensional measurements of an object. Length is the longest horizontal side, width is the shorter horizontal side, and height is the vertical measurement from base to top.

Q2. What is the correct order of dimensions in packaging?

A: The standard order is Length × Width × Height (L × W × H). This ensures consistency in design, shipping, and storage.

Q3. How can I measure my box correctly?

A: Place the box in its intended position. Use a measuring tape to first measure the longest base side (length), then the shorter base side (width), and finally the vertical side (height). Always measure in the correct order and double-check your units.

Q4. Why does the order sometimes change to height × width × length?

A: The order may change based on the orientation of the product or packaging. For vertically oriented items, height may come first. Always clarify the order with your packaging provider.

Q5. How do I calculate the volume using length, width, and height?

A: Multiply the three values together:

Volume = Length × Width × Height

The result will be in cubic units (e.g., cubic inches or cubic centimeters), useful for shipping calculations.

Q6. Is “depth” the same as height?

A: In some industries, “depth” refers to the same vertical dimension as height. However, it can also mean how far something extends backward. Always check context or ask for clarification.

Q7. Can I use internal dimensions for box design?

A: Yes, but you must specify that you're providing internal dimensions. This ensures your product fits inside the box. If you use external dimensions, consider the box material's thickness.

Final Thoughts

Understanding the differences and proper order of length, width, and height can transform the way you approach packaging. It leads to better-fitting boxes, more cost-effective shipping, and a smoother production process.

At Custom Packaging Pro, we prioritize dimensional accuracy in every custom box design we deliver. Whether you need small product boxes or large shipping containers, our team is here to ensure every inch counts.

Need help measuring your packaging correctly? Reach out to Custom Packaging Pro — we’re here to simplify the process, from dimensions to delivery.